Oil mist emission during operation has long been a persistent headache for users of oil-sealed vacuum pumps. While oil mist separators are designed to effectively resolve this issue, many users continue to observe oil mist at the separator's exhaust port after installation. Most users instinctively suspect poor-quality filter elements as the culprit, assuming incomplete oil mist filtration.

Indeed, inferior oil separator filters with low oil-gas separation efficiency may fail to fully filter the oil mist discharged by vacuum pumps, causing mist to reappear at the exhaust port. However, oil mist recurrence doesn't always indicate defective filters. This is where many vacuum pump users make a mistake - connecting the oil return line incorrectly.

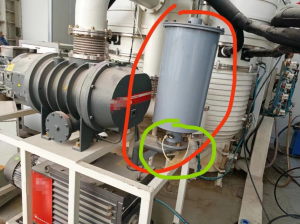

In practice, we've encountered multiple cases where incorrect installation caused separator malfunction. As shown in the diagram above, some users mistakenly connect the oil return line to the separator's inlet port. This pipeline is originally designed to return captured oil droplets to either the vacuum pump's oil reservoir or an external container. However, when incorrectly installed, it inadvertently becomes an alternative exhaust pathway for pump emissions.

A fundamental principle comes into play here: filter elements inherently create airflow resistance. Given the choice between passing through a restrictive filter or taking an unrestricted path, the gas stream will naturally favor the path of least resistance. Consequently, significant amounts of unfiltered gas bypass the filter element entirely. The solution is straightforward – simply reconnect the oil return line to either the vacuum pump's designated oil return port, main oil reservoir, or an appropriate external collection container.

This installation error explains why some properly functioning oil mist separators appear ineffective. Correcting the oil return line configuration typically resolves the issue immediately, allowing the separator to perform as intended. Other potential but less common causes include excessive oil levels in the pump, incorrect separator sizing for the application, or unusually high operating temperatures affecting oil viscosity. However, installation verification should always be the first troubleshooting step before considering these other factors.

Post time: Jul-04-2025