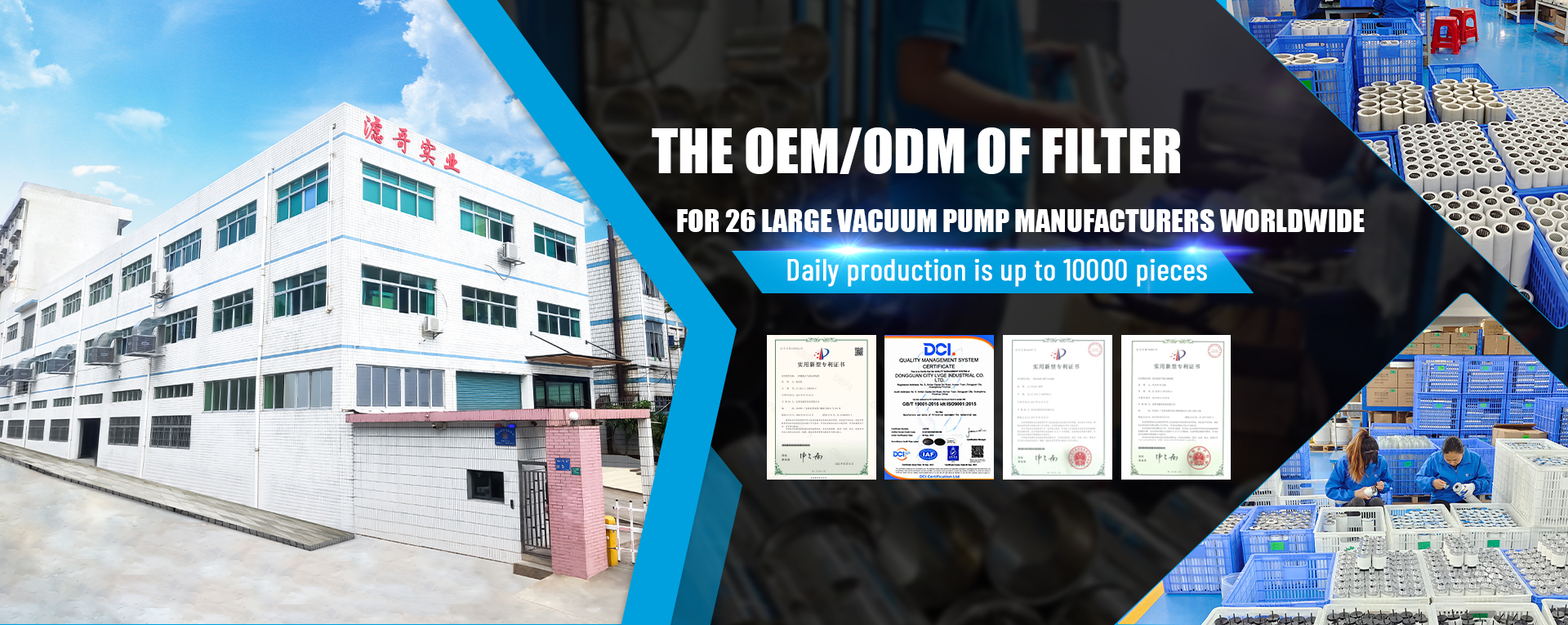

The OEM/ODM of filters

for 26 large vacuum pump manufacturers worldwide

about us

what we do

Dongguan LVGE Industrial Co., Ltd. was founded by three senior filter technical engineers in 2012. It is a member of the “China Vacuum Society” and a national high-tech enterprise, specializing in the research and development, production, and sales of vacuum pump filters. The main products include intake filters, exhaust filters and oil filters. At present, LVGE has more than 10 key engineers with over 10 years of experience in the R&D team, including 2 key technicians with over 20 years of experience. There is also a talent team formed by some young engineers. Both of them are jointly committed to the research of fluid filtration technology in industry. As of October 2022, LVGE has become the OEM/ODM of filter for 26 large vacuum pump manufacturers worldwide, and has cooperated with 3 enterprises of Fortune 500.

more >>news