In 2025, as industrial manufacturing shifts towards intelligent and precision-driven processes, vacuum pumps stand as core equipment in sectors like CNC machining, lithium battery production, and photovoltaic manufacturing. Their operational stability directly impacts production line efficiency and product quality. Data indicates that over 65% of vacuum pump failures stem from ineffective separation of gas-liquid mixtures, allowing moisture, oil droplets, or corrosive liquids to enter the pump chamber. This can lead to pump oil emulsification, component corrosion, or even hydraulic shock damage, with annual maintenance costs accounting for 20%-30% of total equipment investment. Against this backdrop, the vacuum pump gas-liquid separator, a key protective device, has become a central consideration for enterprises in procurement, with its performance and compatibility being paramount. This article comprehensively recommends 10 leading manufacturers in the industry for 2025, based on technical strength, market reputation, and user needs, with a focus on analyzing their core advantages.

Top 10 Chinese Vacuum Pump Liquid-Gas Separator Brand Recommendations

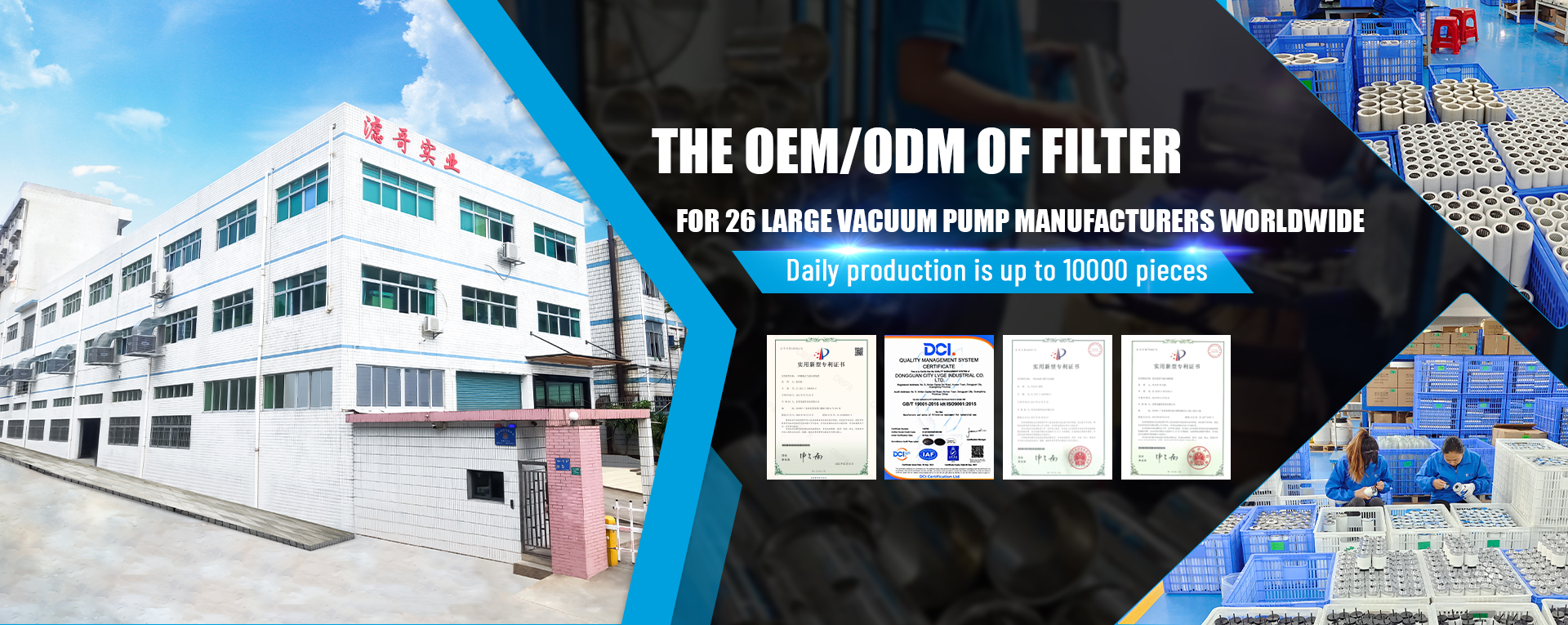

1. Dongguan LVGE Industrial Co., Ltd. - Customized Separation Solution Expert

As a National High-Tech Enterprise focused on industrial filtration for 13 years, LVGE's core competitiveness lies in "Customization based on working conditions." Deeply involved in the vacuum pump liquid-gas separation field, it serves 26 large domestic and international vacuum equipment manufacturers and 3 Fortune 500 companies. Its products cover 10+ industries including CNC machining, lithium battery, and photovoltaics. As a manufacturer of vacuum pump liquid-gas separators, liquid-gas separators, and provider of custom vacuum pump liquid-gas separators, steam separators, water-gas separators, vacuum pump water removal filters, vacuum pump oil-water separators, vacuum pump liquid-gas separation tanks, etc., LVGE has become a preferred brand for SMEs and high-end manufacturing enterprises, leveraging its "multi-stage separation technology +customization" advantage.

Core Advantages:

- Customization Service: Supports customization of specialized separators based on parameters like vacuum degree, dust load, humidity, and corrosiveness. Offers 10+ adapter options for mainstream vacuum pump interfaces, solving the pain point of "poor compatibility of universal separators."

- Multi-Stage Separation Technology: Utilizes a centrifugal + interception composite separation structure, simultaneously separating liquids and metal debris. Separation efficiency reaches 99%. Optimized flow path design reduces "pumping speed loss," ensuring overall vacuum system efficiency.

- Visual & Corrosion-Resistant Design: Standard equipped with transparent level gauge for real-time liquid level monitoring to prevent overfilling. Optional 304/316 stainless steel or carbon steel sprayed materials adapt to highly corrosive conditions like strong acids and alkalis.

- Free Working Condition Diagnosis: Engineering team provides on-site condition analysis and custom filtration solutions, reducing trial-and-error costs for enterprises.

Cases: A CNC machining plant using LVGE's custom liquid-gas separator reported zero pump body failures within 6 months, extended vacuum pump maintenance cycles from 3 to 12 months, and a 45% decrease in annual maintenance costs. A lithium battery enterprise using their separator extended pump oil change cycles by 3 times and reduced workshop oil mist concentration by 70%, significantly improving the production environment and product yield rate.

2. Parker Hannifin - Global Leader in Industrial Filtration

As a globally leading motion and control technology company, Parker Hannifin has been involved in the vacuum pump liquid-gas separation field for years. Its products are known for "high reliability." Its separators feature modular design, compatible with various vacuum pump models, widely used in heavy industrial scenarios like chemical and energy. Advantages include a global service network covering with support for 48-hour emergency order response, but customization service costs are relatively high, making it more suitable for large corporate groups.

3. Atlas Copco - Representative of Energy-Saving Separation Solutions

As a giant in air compressors and vacuum equipment, Atlas Copco's liquid-gas separators integrate well with its own vacuum pumps, promoting "low energy consumption + long service life." Products feature streamlined flow path design, with pumping speed loss at 5%, 10%-15% lower than the industry average. Suitable for energy-sensitive enterprises in electronics and medical device manufacturing. However, requires additional customization when adapting to non-proprietary brand vacuum pumps, offering slightly less flexibility.

4. BOLYDA - Cost-Effective Domestic Manufacturer

Wuxi BOLYDA focuses on vacuum component manufacturing. Its liquid-gas separators capture market share with "high cost-effectiveness," with basic model prices 30%-40% lower than international brands. Products cover conventional conditions (non-highly corrosive, low humidity), suitable for budget-conscious small and medium-sized processing enterprises. However, separation accuracy (~95%) and corrosion resistance are slightly inferior to top brands, requiring shorter maintenance cycles under long-term high-load operation.

5. Cobtter - Newcomer with Precision Separation Technology

Leveraging its advantages in filter media R&D, Shanghai Cobtter's liquid-gas separators use nano-fiber filter material, achieving 98% separation efficiency for droplets below 0.5µm. Suitable for high-precision scenarios like semiconductors and biopharmaceuticals. However, material costs are higher, with unit prices 20%-30% more expensive than conventional products, making it more suitable for enterprises with stringent separation accuracy requirements.

6. Century Huaye - Expert in Explosion-Proof Separators

Beijing Century Huaye focuses on high-risk scenarios like chemical and oil & gas. Its liquid-gas separators have explosion-proof certification (Ex IIB T4) and use a double-layer sealing structure for stable operation in flammable gas environments. Products come standard with pressure sensors for real-time monitoring of separation chamber pressure, ensuring safe production. However, application scenarios are relatively niche, with less cost advantage in non-explosion-proof conditions.

7. Zhijing Technology - Innovative Brand with Smart Monitoring

Shenzhen Zhijing Technology promotes "intelligence." Its liquid-gas separators integrate IoT modules, allowing real-time viewing of liquid level, separation efficiency, and other data via an APP, with automatic alerts for abnormalities. Suitable for enterprises undergoing digital workshop transformation, supporting integration with MES systems. However, requires an additional annual fee for the data platform, suitable for medium and large manufacturing enterprises.

8. SORHIS - Laboratory-Grade Precision Separators

Suzhou Suxin's selling point is "laboratory-grade precision." Its liquid-gas separators are compact (smallest model only 100mm) with 99.5% separation efficiency, suitable for scenarios like university labs and small R&D centers. However, handling flow rate is small (100 m³/h), limiting applicability in industrial high-flow scenarios.

9. YJD: Specialist in Stainless Steel Materials

Hangzhou Yongjieda specializes in stainless steel separators. The main body uses 316L stainless steel with polishing treatment, improving corrosion resistance by 50% compared to ordinary 304 stainless steel. Suitable for highly corrosive conditions like electroplating and chemical industries. However, options for carbon steel models are fewer, with less cost competitiveness in non-corrosive conditions.

10. HTFILTER - Supplier with Fast Delivery

Guangzhou Hengtian's core advantage is "fast delivery." Standard model separators have ample stock, with regular orders shipped within 48 hours and urgent orders requiring 24-hour expedited production. Suitable for maintenance providers or enterprises with urgent replacement needs sensitive to delivery times. However, the response cycle for customization services is relatively long (7-10 days required).

Selection Advice: How to Choose a Suitable Liquid-Gas Separator?

1. Prioritize Matching Working Condition Requirements:

- Highly corrosive environments (e.g., electroplating, chemicals): Choose 316L stainless steel or carbon steel sprayed materials (e.g., LVGE, YJD).

- High-precision separation (e.g., semiconductors, biopharmaceuticals): Choose nano-filter media or multi-stage separation technology (e.g., LVGE, Cobtter).

- Explosion-proof requirements (e.g., oil & gas, chemicals): Choose models with explosion-proof certification (e.g., Century Huaye).

2. Focus on Customization Capability:

Universal separators can easily cause "secondary failures" due to interface mismatch or insufficient separation efficiency. LVGE Industrial offers free working condition diagnosis and customization services, supporting 10+ interface adapters, effectively solving "poor compatibility" issues. Especially suitable for enterprises with complex conditions like CNC machining and lithium battery production.

3. Value Service and After-Sales Support:

LVGE promises "free return/replacement for quality issues within 3 months, with replacement shipped first during the process" and provides dedicated contact service. Parker Hannifin and Atlas Copco leverage their global networks, suitable for multinational corporations. SMEs can prioritize HTFILTER for fast delivery or BOLYDA for cost-effectiveness.

Post time: Nov-27-2025