At the forefront of precision manufacturing and scientific research, vacuum technology is the silent cornerstone. From chip etching to drug purification, from laboratory exploration to food packaging, the quality of the vacuum environment directly determines the success or failure of a product. In this battle for "purity," the vacuum pump is its heart, and the vacuum pump oil mist filter is the "ultimate guardian" protecting this heart from the external environment.

The following are manufacturers and brands recognized as leading in the vacuum field. These brands are widely recognized by vacuum technology engineers and users, and are generally divided into two categories: professional filter manufacturers and mainstream vacuum pump manufacturers (original equipment manufacturer filters).

I. Professional Oil Mist Filter Manufacturers (Third-Party Brands, Compatible with Multiple Brand Pumps)

These brands do not produce vacuum pumps, but they specialize in filtration and separation technology. Their filters are compatible with various vacuum pump models, including Busch, Leybold, and Edwards, and are typically known for their high performance and cost-effectiveness.

Pall

Position: High-end filter manufacturer, specializing in exhaust gas treatment under extremely special vacuum conditions.

Vacuum Applications: Pall's VacuGuard series is specifically designed for vacuum pump exhaust. In semiconductor, LED, and photovoltaic processes, vacuum pumps discharge corrosive and toxic process gas byproducts. Pall's filters provide complete solutions from oil mist condensation and particulate filtration to chemical adsorption (neutralizing acidic gases).

Features: Highest technological barriers, most comprehensive product line, the first choice for handling harsh operating conditions.

Donaldson

A global giant in industrial filtration, with a very high market share in the general vacuum market.

Vacuum Applications: Its UltraPleat VP and Duralife VE series oil mist filters are standard in many industrial vacuum applications. Donaldson offers filters for various vacuum pumps, including rotary vane pumps and screw pumps, renowned for their superior oil mist capture efficiency and long service life.

Features: Excellent global supply network, a reliable choice for many vacuum pump manufacturers and users.

Camfil

A leading European air filtration company with a strong foundation in the vacuum field for its industrial filtration products.

Vacuum Applications: Camfil's oil mist filters utilize highly efficient condensation technology, effectively reducing oil discharge and protecting the environment and equipment. They are highly favored in the European market, especially in the chemical and pharmaceutical industries.

Features: Reliable product performance, meeting stringent European environmental standards.

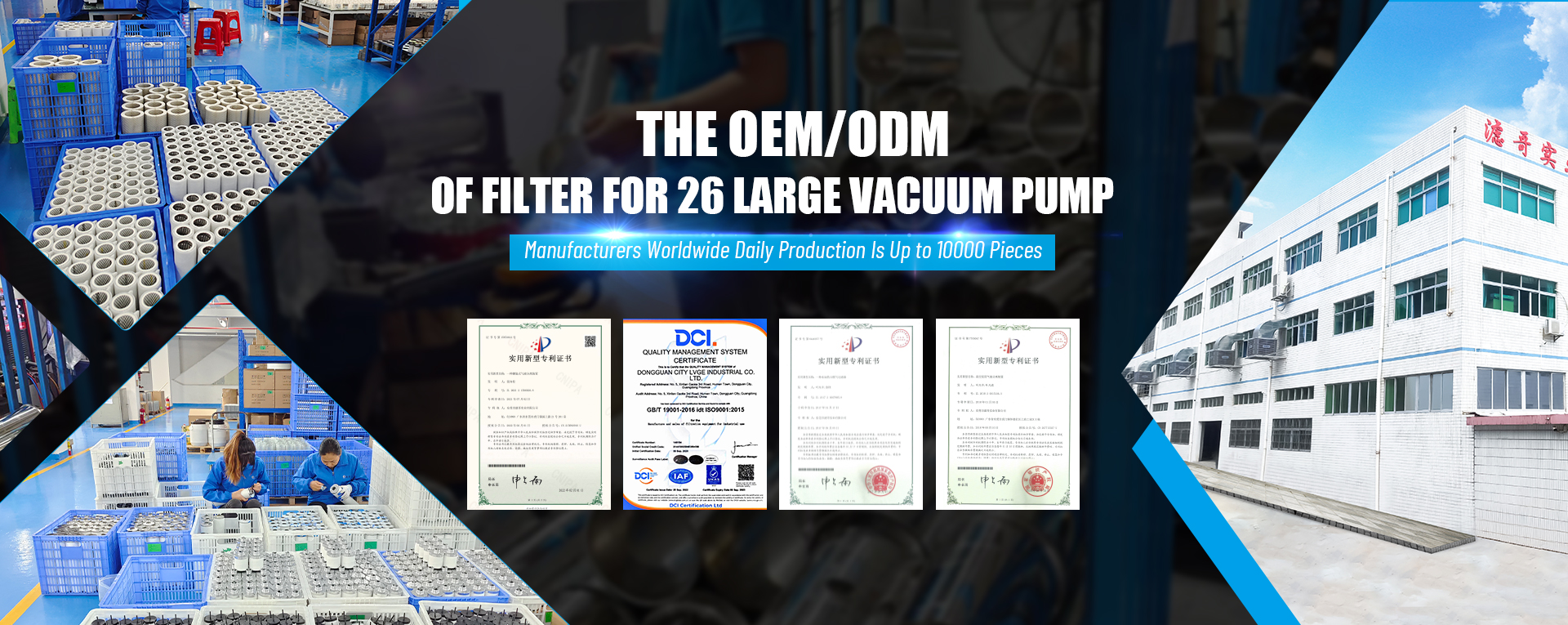

LVGE

A leading Chinese vacuum pump filter manufacturer. Although a latecomer, it has rapidly risen to prominence, dominating the mid-to-high-end market in China and gradually expanding into international markets.

Vacuum Applications: Uses imported German glass fiber from the same supplier as Busch to produce oil mist filters, providing replacement filters for mainstream vacuum pumps. A featured product is the dual-element exhaust filter, offering more efficient and longer-lasting filtration. Currently, it collaborates with 26 large vacuum equipment manufacturers, gradually becoming a filter manufacturer or supplier for some mainstream vacuum pumps.

Features: High cost-performance ratio, strong expertise in the vacuum pump field.

Mainstream Vacuum Pump Manufacturers (Original Brands)

The advantages of using original vacuum pump filters are 100% compatibility, optimal performance matching, and ensuring no impact on the pump's warranty. However, the price is usually higher than third-party compatible brands.

1. Busch

- One of the world's largest vacuum pump manufacturers.

- Vacuum Applications: Provides a full range of original equipment manufacturer (OEM) oil mist filters for its extensive product line, including rotary vane pumps, screw pumps, and claw pumps. These filters are specifically designed for Busch pumps, ensuring optimal oil-gas separation and minimal oil discharge.

- Features: Original equipment manufacturer (OEM) quality assurance; global service network for convenient purchase and replacement.

2. Pfeiffer

- Renowned in the high vacuum and ultra-high vacuum fields.

- Vacuum Applications: Provides high-performance OEM exhaust filters for its rotary vane pumps, screw pumps, etc. Pfeiffer Vacuum has extremely high purity requirements; its filters effectively protect pump oil from contamination and ensure clean exhaust.

- Features: Excellent quality, particularly suitable for applications requiring high cleanliness and vacuum levels, such as analytical instruments and scientific research.

3. Leybold

- A long-established and globally renowned provider of vacuum technology.

- Vacuum Applications: Leybold provides dedicated oil mist filters for its rotary vane pumps, dry pumps, etc. Its filter element design prioritizes efficient separation and long lifespan, making it a standard configuration for Leybold vacuum systems.

- Features: Mature technology, stable performance, and a reliable choice for original equipment manufacturer (OEM) spare parts.

4. Edwards

- A leader in the semiconductor and scientific vacuum markets.

- Vacuum Applications: Edwards offers dedicated exhaust filters for its dry pumps and rotary vane pumps. For its robust dry pump product line, its filters are specifically designed to handle challenging process gases.

- Features: Highly targeted, especially excelling in its expertise in semiconductor process exhaust gas treatment.

In the sophisticated edifice of vacuum technology, the oil mist filter, though a small component, carries immense responsibility. Whether it's Pall's technological pinnacle, LVGE's professional capabilities, or the quality assurance of major vacuum pump manufacturers, they collectively form a crucial line of defense ensuring the smooth flow of global industrial lifelines. Making an informed choice is not only about protecting equipment but also a profound investment in corporate productivity, environmental responsibility, and future development.

Post time: Nov-01-2025