In addition to the chemical industry, many industries also need to synthesize a new material by stirring different raw materials. For example, the production of glue: stirring raw materials such as resins and curing agents to undergo chemical reactions and generate glue. The lithium battery industry is no exception.

Lithium battery slurry must have good stability, which is an important indicator to ensure battery consistency in the production. Therefore, it is very important to mix and disperse the slurry. After being dispersed by a mixer, the slurry can further disperse and homogenize the fine powder clusters or solid particle aggregates in the solution, and then obtain sufficiently small solid particles, evenly distribute them in the solution.

During stirring, air will enter the slurry to form bubbles. These bubbles will affect the quality of the slurry, so vacuum degassing is required, which means discharging gas from the slurry through the pressure difference. To prevent a few water from being sucked into the vacuum pump, we need to install a gas-liquid separator. If some raw materials are corrosive and highly volatile, a condenser needs to be assembled. Generally, in addition to the slurry, there are also a large amount of dust, resin, and curing agent. They are easy to be sucked into the vacuum pump and damage the pump. So an intake filter is also needed to protect the vacuum pump. Some gas-liquid separators can not only remove a small amount of liquids but also filter dust, like the one shown in the bottom left image.

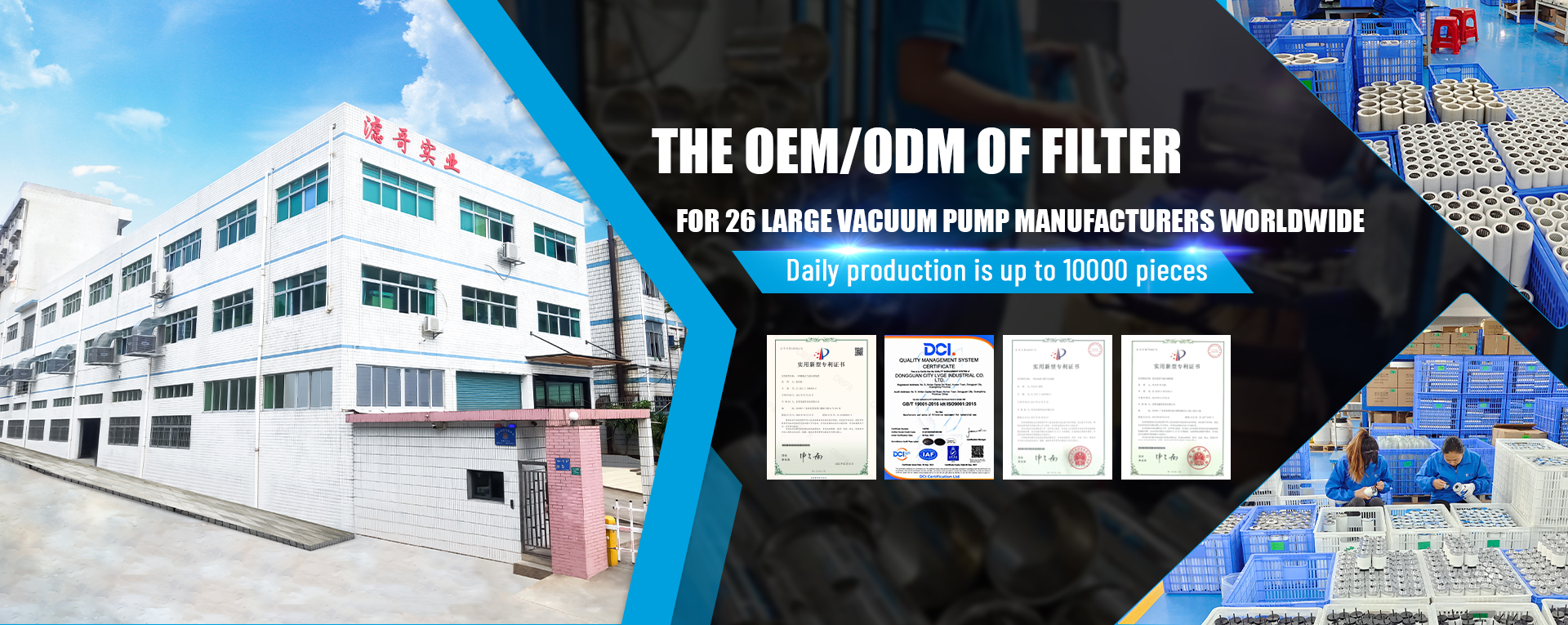

LVGE has specialized in vacuum pump filter for 15 years, and we are still exploring other vacuum application areas. In the cooperation, both LVGE and customers gradually deepened the trust. We are constantly improving the technology and products with the help of our customers. Recently, LVGE have had close exchanges with customers in the lithium battery industry and learned a lot from them. And we will continue to talk about other processes in the lithium battery industry where vacuum technology is applied. If you are interested, you can follow us or contact us.

Post time: Mar-02-2024