Vacuum Pump Oil Leakage: Assembly & Oil Seal Springs

Oil leakage often starts at the assembly stage. During press-fitting or installation, improper handling can deform the oil seal or scratch the sealing lip, immediately compromising sealing performance. Equally critical is the oil seal spring: if its elasticity does not meet design requirements or if the spring material is poor and fatigues early, the seal cannot maintain proper contact pressure and will wear abnormally. Both problems—assembly damage and spring failure—are primary mechanical causes of leakage. To prevent them, use certified seals and springs, follow correct press-fit procedures, avoid metal-to-rubber abrasion during installation, and perform a torque check after assembly.

Vacuum Pump Oil Leakage: Oil Compatibility & Exhaust Oil-Mist Filters

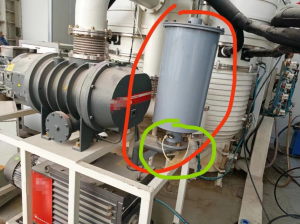

The lubricant itself has a direct chemical effect on seal materials. Some oils or additives can cause elastomers to harden, swell, soften, or crack over time; once the seal material degrades, leakage becomes inevitable. Therefore, always select lubricants that are explicitly compatible with the pump’s seal material and follow manufacturer recommendations. For oil spray (mist) at the exhaust, the presence and quality of an oil-mist filter at the pump outlet is decisive: a missing, clogged, or low-quality filter allows oil aerosol to escape and be mistaken for seal leakage. Regularly inspect and replace exhaust filters, and choose coalescing or multi-stage filters sized for your pump’s flow and operating conditions to reduce spraying.

Vacuum Pump Oil Leakage: System Seals & Operating Practices

Leakage is not limited to the primary oil seal—any O-ring, gasket, cover, flange, or port seal inside the pump can fail and cause oil loss. Factors such as heat, chemical exposure, particulate abrasion, or cumulative wear will degrade these components. Operational practices also influence leakage risk: running the pump beyond its design limits, frequent start-stop cycles, neglecting scheduled filter or oil changes, or failing to address small misting early can all accelerate seal failure. Implement a preventive-maintenance program: inspect all seals during service intervals, monitor oil consumption and sight-glass levels, log differential pressure across filters, and replace worn seals before failure.

In short, the four core causes of vacuum pump oil leakage are: improper assembly, oil seal spring failure, incompatible oil (affecting seal materials), and failure of seals elsewhere in the pump (including inadequate exhaust filtration or poor operating practices). Addressing these points—quality parts and springs, compatible lubricants, effective oil-mist filtration, careful assembly, and disciplined maintenance—will greatly reduce both oil leakage and oil-spray problems, improving pump reliability and lifetime.

Post time: Sep-18-2025